- Home

- Cooling Towers

Hard water in cooling towers can cause a number of problems, including.

Scaling

Hard water with high calcium levels can cause the water to form scales, which can reduce the cooling tower’s efficiency.

Corrosion

Hard water can cause corrosion in the cooling tower, which can lead to costly repairs or even replacement of the tower.

Fouling

Hard water can contribute to fouling and bacterial contamination, which can eat away at the piping surfaces.

Reduced heat transfer

Hard water can reduce the effectiveness of heat transfer, which can increase running & energy costs.

But simple and perfect Solution is Care-Free Water Conditioners.

Consider the benefits

You see a Care-Free Water Conditioner will…

Care-Free Water Conditioner compliments

any industrial or commercial application where water is used

BEFORE WITH CHEMICALS

A chemically treated cooling tower prior to installation.

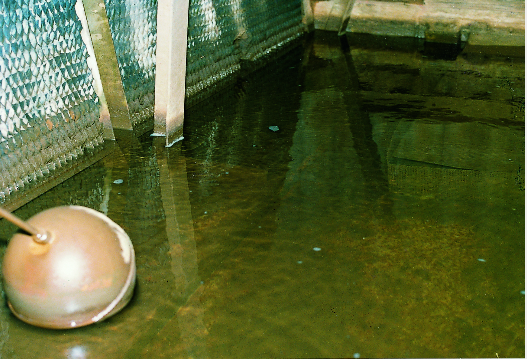

AFTER EIGHT MONTHS, WITHOUT CHEMICALS

Note the water clarity of the cooling tower sump. Care-Free virtually eliminated the biofilm maintenance is required to keep the tower in a ‘clean’ condition.

RANGE OF SIZES TO SUIT YOUR FLOWRATE

Flowrates: 12 lit/min to 15300 lit/min

Test Result at Aquatic Environment of Cooling Towers!

What was of major significance, and is possibly the most important point of this test, is that during the two-year experiment:

a) The cooling tower is dispersing neither Legionella or biocide aerosols.

b) The cooling tower no longer requires cleaning except for the requirement to de-sludge the water pan.

c) The shell and tube condensers attached to the refrigeration machinery no longer require cleaning or brushing.

d) An additional benefit of item (b) is that the compressor efficiency is not impaired or reduced because of dirty or scaled condenser tubes.

e) The use of cooling tower chemicals has been eliminated subject to the Total Bacterial and Legionella counts remaining below a specified limit.

Throughout this time, the test results as provided by a NATA certified testing agency have identified the lowest detectable levels of all legionella. This is an excellent result for cooling towers which are using chemicals, but is an exceptional result from cooling towers which are using no biocide or algaecide chemicals